Recessed LED Aluminium Profile For Led Strips Lighting With Spring Clip

| Name | aluminum alloy profile, led aluminum channel, led strip light profile, led strip profile, extruded aluminum led housing, u shaped aluminum channel, aluminum channel for led strip lights, aluminium profile for led strips, aluminum led profile housing |

| Material | Aluminium Extrusion Profile 6063 |

| Shape | Flat, U-Shape, Round or Customized, L, various shapes |

| Length | 2.5m or 2.7m, can be customized |

| Surface Treatment | Anodized, Polished, Electrophoresis, Electroplate |

| Color | Sliver, Black, Gold, Golden, customized |

| Feature | Easy install, Smooth surface, Grace surface |

| Package | Stick transparent film every piece, 100 pieces in 1 carton |

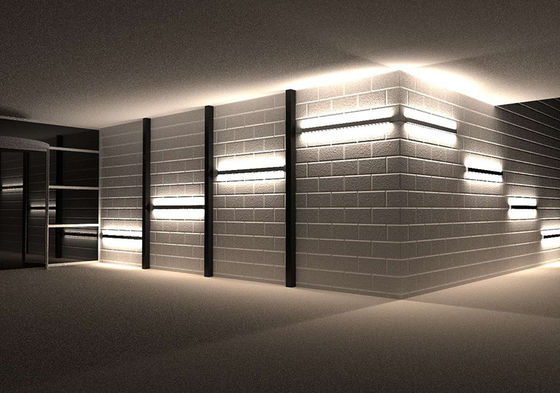

| Application | Decorations, Door & Window, Heat Sink, LED, Shed |

| Installation Introduce | Screwed, Surface mounted, glued or mounted, recessed mounted |

LED aluminum extrusion profile, led chandelier/led office lighting/led lighting/led aluminum frame. Many LED downlights nowadays are made of aluminum, and the cost of plastic is low. If the quality is good, aluminum alloy is used to make the face ring. Those cheaper downlights will use plastic to make the face ring in order to reduce the cost, but this is not conducive to the heat dissipation of the downlight. There are also "stainless steel clad steel pipes" that are made of stainless steel on the outside and welded steel pipes on the inside, which are cheap and good quality.

![]()

1. LED lamps need materials with good heat dissipation, and aluminum has a much larger thermal conductivity than steel, which is conducive to light heat dissipation.

2. Aluminum profile is easy to process.

3. There is a layer of dense alumina on the surface of aluminum, which has good oxidation and corrosion resistance.

4. Aluminum is cheaper than stainless steel.

![]()

![]()

![]()