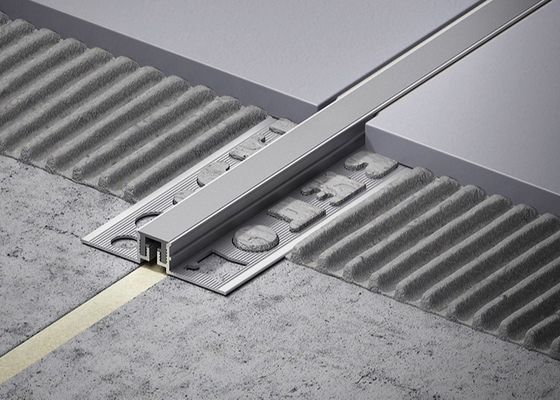

| Name | Install solid wood flooring, Movement joint, silicone glue, conference rooms, ceramic tiles, alloy 6063, Aluminium extrusion profiles, Aluminum Movement Joint |

| Material | Aluminium Alloy 6063 |

| Right Angle Size | 15mm / 2.5cm, other size 10mm, 20mm, 25mm, 30mm |

| Length | 2.5m or 2.7m, can be customized |

| Surface Treatment | Anodised, |

| Color | Silver or other color can be made,such as Shiny Gold, Matt Gold, Rose Gold,Champagne, Glossy Bronze |

| Feature | Easy install, Smooth surface, Grace surface |

| Package | Stick transparent film every piece, 100 pieces in 1 carton |

| Application | Mainly used for exterior corner of ceramic tiles, stone, glass, wood in the warehose,,retail cafes & restaurants, corridors, lobbies, offices, store rooms, classrooms, conference rooms, back of house areas. |

| Installation Introduce | Using silicone glue / titebond paste to bond with other materials such as brick, stone, wood, glass. |

Many families who install solid wood flooring have the most common problems after they move in that the floor is deformed, arched, and cracked, and it is troublesome to repair. In fact, most of these problems are caused by carelessness during construction. How to avoid solid wood flooring Deformation, arching, or gaps?

![]()

1. Choose high-quality wood flooring, the shrinkage ratio of wood flooring of different materials is different, and the shrinkage ratio of high-quality wood flooring is smaller.

2. Choose wood flooring with better processing technology.

3. Keep shrinkage joints and use movable joints to ensure that there is a buffer zone when the wooden floor shrinks or expands.

![]()

![]()

![]()